Company

Learn About Xinxing Light Alloy

Establishment Time

Cover An Area

Annual Production Of Aluminium Grain Refining Agent

Annual Production Of Aluminium Based Intermediate Alloys

Annual Production Of Aluminium Sheet, Strip And Foil

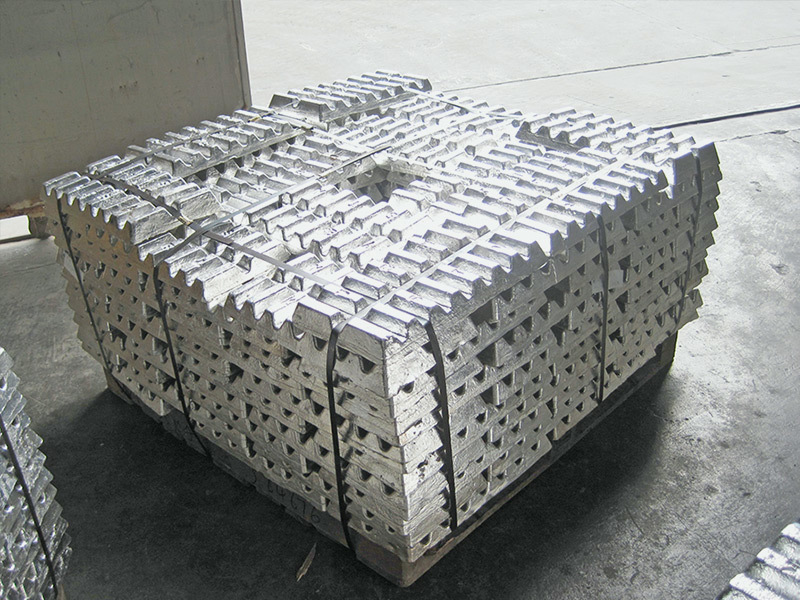

Xinxing Light Alloy Material (Luoyang) Co., Ltd. was established on October 11, 2017 with a registered capital of 0.587 billion, and is a wholly-owned subsidiary of Shenzhen Xinxing Light Alloy Material Co., Ltd. Mainly engaged in aluminium grain refiner, aluminium-based intermediate alloy, particle refining agent, non-ferrous metal light alloy materials, KA1F4 research and development, production and sales. The company covers an area of about 350 acres and has an annual production capacity of 60000 tons of aluminium grain refiner and 80000 tons of aluminium-based intermediate alloys (AlMn80, AlCr40, AlFe60, AlSi70).

The company has successively won the honorary titles of high-tech enterprise of the national torch plan and advanced unit of "six modernizations" construction of small and medium-sized enterprises in 2020, and successfully authorized and established Henan aluminium-based light alloy metallurgical accessories engineering technology research center and Luoyang light alloy metallurgical accessories enterprise research and development center. It has passed the ISO9001, ISO14001, ISO45001, weapons and equipment quality management system certification, energy management system certification and QC080000 certification.

The high-performance mother aluminium alloy produced by the company is the parent alloy that changes and improves the performance of aluminium alloy materials in the world. The manufacturing technology and quality level of aluminium grain refiner alloy materials are at the priority level, and it is the world's largest manufacturer of mother aluminium alloys, as well as a mother aluminium alloy manufacturer with a complete industrial chain (from raw ore mining to end alloy processing). The titanium-based alloy produced by the company is an important national strategic material, which is widely used in military industry, aviation, aerospace, navigation, rail transportation and other fields. It is a light alloy material required by large military enterprises in my country. The new aluminium electrolysis energy-saving material produced by the company is a new energy-saving material that improves the current efficiency of aluminium electrolysis, reduces the electrolysis temperature and reduces the power consumption of aluminium electrolysis.

The company has established a long-term industry-university-research cooperation relationship with Central South University, Northeastern University and Henan University of Science and Technology to improve the company's scientific and technological innovation ability and market competitiveness, and work together on the research and development of aluminium-based light alloy metallurgical accessories and the transformation of achievements. The company has an innovative R & D team composed of professors, doctors and engineers, equipped with advanced scientific research instruments such as X-ray fluorescence analyzer, X-ray diffractometer, inductively coupled plasma spectrometer, ONH analyzer, metallographic microscope, automatic turning and milling machine, grinding prototype, vacuum induction furnace, etc., to support the research and development of new material products of the company. Up to now, the company has 5 core invention patents for its main products, 8 invention patents, 10 utility model patents, and has realized the transformation of a number of patents, new processes, new products, new equipment and standards, bringing significant economic benefits to the enterprise.

The company is committed to the technological innovation of aluminium-based light alloy metallurgical accessories, promoting the improvement of the performance of building materials, automobiles, rail transit, and aerospace materials, conforming to the green development trend, helping the development of my country's new material industry, achieving energy conservation and emission reduction, and protecting the earth's environment.

Research And Development And Manufacture Of Aluminium Master Alloy Of Science And Technology Production Enterprises

Enterprise Culture

We are willing to provide high-quality products and services with high-quality product quality, perfect after-sales service, excellent marketing concept and reasonable product price. We sincerely welcome customers to visit, guide and seek common development!!

Mission

Prosper academic research on new light alloy materials, achieve domestic production of special light alloy materials in line with the world's technological level, and make substantial contributions to the development of the world's light alloy material industry.

Vision

Become an advanced, large-scale and good quality manufacturer of special light alloy materials

Values

unity forge ahead efficiency benefit

Development Process

development path