Aluminium Alloy Uses-Main Uses of Aluminium Alloys

Release time:

2021-06-17

According to the composition of aluminium alloy and the characteristics of the production process, it is generally divided into two categories: deformed and forged aluminium alloy. The key used in industrial production are aluminium-manganese, aluminium-magnesium, aluminium-magnesium-copper, aluminium-magnesium-silicon-copper, aluminium-zinc-magnesium-copper and other aluminium alloys. Deformation aluminium alloy is also called cooked aluminium alloy. According to its composition and characteristics, it is divided into five kinds of anti-rust treatment aluminium, hard aluminium, super hard aluminium, forged aluminium and aluminium.

According to the composition of aluminium alloy and the characteristics of the production process, it is generally divided into two categories: deformed and forged aluminium alloy. The key used in industrial production are aluminium-manganese, aluminium-magnesium, aluminium-magnesium-copper, aluminium-magnesium-silicon-copper, aluminium-zinc-magnesium-copper and other aluminium alloys. Deformation aluminium alloy is also called cooked aluminium alloy. According to its composition and characteristics, it is divided into five kinds of anti-rust treatment aluminium, hard aluminium, super hard aluminium, forged aluminium and aluminium.

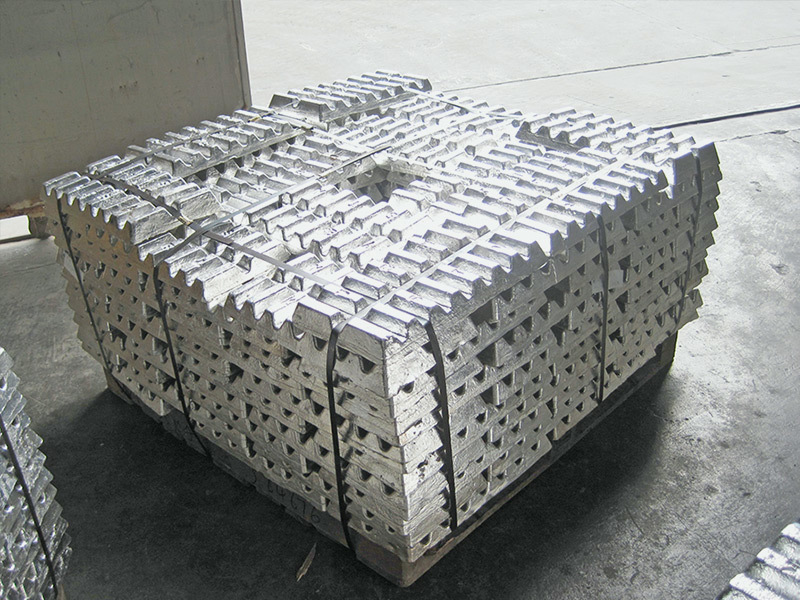

aluminium alloy is made of pure aluminium with some aluminium alloy elements, such as aluminium-manganese aluminium alloy, aluminium-alloy copper, aluminium-copper-magnesium hard aluminium alloy, aluminium-zinc-magnesium-copper superhard aluminium alloy. aluminium alloy has stronger physical properties than pure aluminium: easy, high performance, wide application field, good decorative design effect, colorful pattern. aluminium alloy is divided into anti-rust treatment aluminium, hard aluminium, super hard aluminium and other types, all kinds of categories have different application areas, and have different numbers for users to use.

aluminium alloy still maintains the characteristics of light, but the physical properties are significantly enhanced. The use of aluminium alloy raw materials has the following three levels: first, as a prefabricated component; second, as doors, windows, tubes, covers, shells and other raw materials; third, as decorative design and thermal insulation materials. The use of aluminium alloy anode * oxidation treatment to solve the problem can carry out the characteristics of coloring, making a variety of decorations. aluminium alloy plate and aluminium profile surface layer can carry out anti-corrosion, embossing, spraying, packaging and printing, etc., and make various decorative materials and aluminium profiles as building decoration materials.

Low cost, and the application of a production process can produce many of the same parts, which is also one of his characteristics.

Its raw material is characterized by light, easy, and its ability to withstand compressive strength level does not like carbon fiber has a larger force category.