Magnesium master alloy is a light metal structural material

Release time:

2021-06-17

Magnesium intermediate alloy is a lighter metal structural raw material, the proportion is only 1.8, each is 1/3 of aluminium and 1/4 of iron, its specific strength reaches 133, can be compared with the specific strength of titanium, which makes magnesium alloy can be used as a high toughness raw material. Production and processing of new materials as the main body of the enterprise, has a detailed, scientific research quality system management. Key markets sell new metal composites such as titanium, magnesium, nickel, tungsten, cobalt, zirconium, and molybdenum.

Magnesium intermediate alloy is a lighter metal structural raw material, the proportion is only 1.8, each is 1/3 of aluminium and 1/4 of iron, its specific strength reaches 133, can be compared with the specific strength of titanium, which makes magnesium alloy can be used as a high toughness raw material. Production and processing of new materials as the main body of the enterprise, has a detailed, scientific research quality system management. Key markets sell new metal composites such as titanium, magnesium, nickel, tungsten, cobalt, zirconium, and molybdenum.

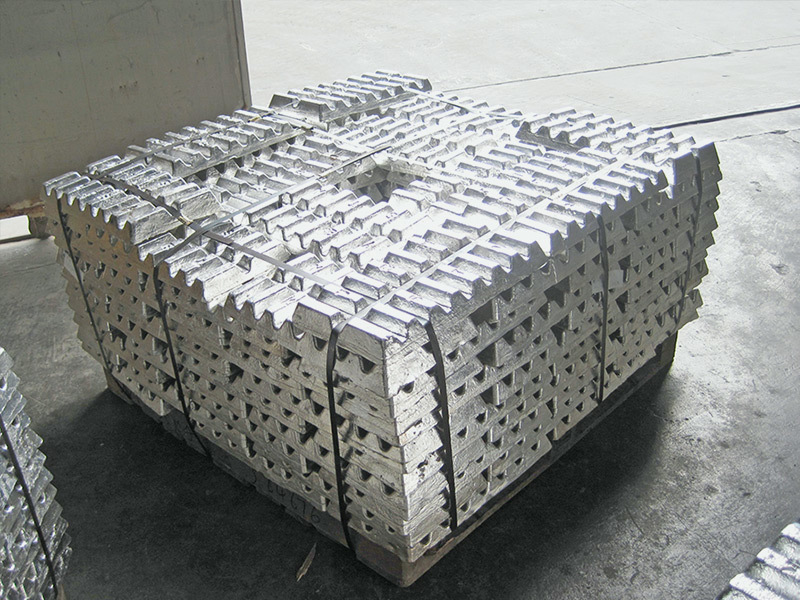

The product development, manufacturing and marketing of magnesium intermediate alloy and magnesium alloy products are the key, and automatic equipment such as melting furnace, continuous extrusion machine, aluminium die casting machine, metal surface treatment production line and so on are introduced. Now it has the ability to produce and manufacture various types of magnesium alloy products such as magnesium alloy plates, pure magnesium plates, magnesium alloy aluminium profiles, magnesium extrusion rods, magnesium plate ingots, etc.

Magnesium alloy according to the production and manufacturing process of magnesium alloy can be divided into two categories, wrought magnesium alloy and forged magnesium alloy, with excellent mechanical equipment performance, the key to automotive parts, parts shell and communication equipment. Compared with wrought magnesium alloy, AZ31B wrought magnesium alloy has higher compressive strength and stronger plastic deformation, which is the key to metal sheet, extrusion molding and cast steel parts.

The addition of AL and ZN elements in magnesium master alloy can improve the structural and mechanical properties and production and processing properties of the alloy. The compressive strength of the alloy expands with the increase of AL content in a certain range. When the ZNAL content is 3% (quality) or so, the elongation of the alloy reaches a larger value. When the ALZN content exceeds 3% (quality), β phase is easily precipitated in the forging mechanism, thus reducing the production and processing properties of the alloy, the compressive strength of AZ31B magnesium alloy is 245-274.4MPa, which is relatively low in the compressive strength performance of magnesium alloy, and can not be improved according to the heat treatment process, but its forgeability.